Cold store curtains that keep the cold out

If you have a cold store or freezer, you know perfectly well that the loss cold means real losses. Every time you open a door, you run the risk of heat, increased energy consumption, moisture, and frost. All of this translates into costs.

Cooling curtains are the answer to this problem – provided they are properly selected and tightly installed. That's why we've prepared a solution that will eliminate your problems.

Specific problems our clients come with:

The cold is escaping, the generators are working at full speed.

Energy costs are rising, yet the temperature in the chamber remains unstable. Each transition means a loss of cooling.

Wet, ice and dangerous conditions.

Warm air flows in, condenses, and freezes. Ice forms on the floor, goods, and appliances.

Work is slow.

Constantly opening and closing doors is a waste of time. And when the door freezes, the problem begins.

We have a solution for this

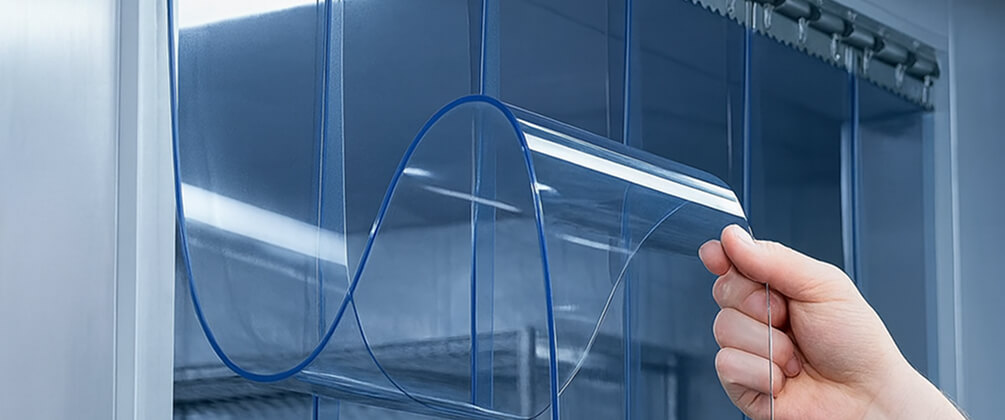

PVC PRO delivers cooling curtains, which were designed specifically for the conditions in cold stores and freezers. They work regardless of how many times a day you open the door – they retain cold, limit the access of moisture and speed up logistics.

They allow people and strollers to move freely.

They are transparent and flexible, even at low temperatures.

Configure your cooling curtain in just a few clicks

Simply enter your dimensions and select the belt type in the configurator, and the system will prepare a ready-made set for you. If you have any questions, please call or email us. We'll be happy to advise you.

Loading configurator...

What belts do we use?

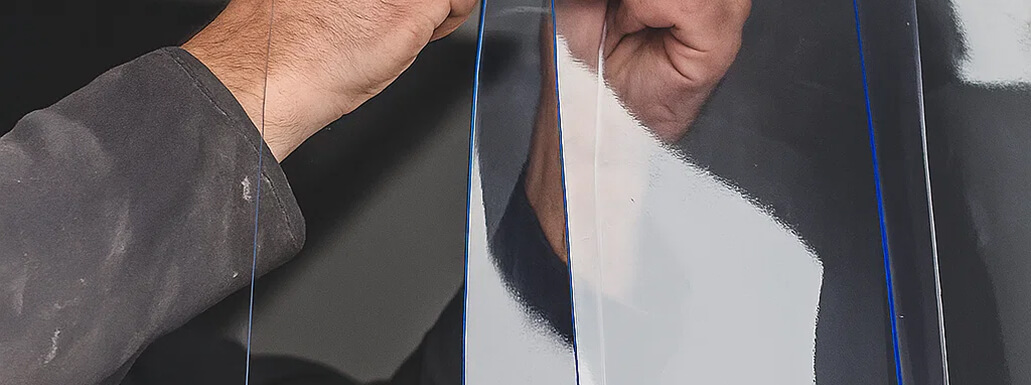

For cold storage we use special cooling belts, which remain flexible even at very low temperatures. They are resistant to cracking, frosting, and hardening.

Is assembly difficult?

No. You get a complete kit – with the straps already attached. You don't have to cut, measure, or figure out what goes with what. Installation usually takes 30–60 minutes.

What if something doesn't add up?

We're on the other side. If you have any questions, you can call or write, and a technical advisor will help you choose the right set – or walk you through the configurator step by step.

What is worth knowing about cooling curtains?

1

Types of PVC foil for cooling curtains

We use special cooling curtains "POLAR" PVC foils adapted to work at low temperatures. Unlike standard belts, refrigeration materials remain flexible even in sub-zero temperatures and do not crack when bent.

We most often use the following variants:

POLAR cold store foil

– designed to work in temperatures down to -25°C, flexible and transparent, ideal for cold rooms and internal openings.

POLAR cold store foil

– designed to work in temperatures down to -25°C, flexible and transparent, ideal for cold rooms and internal openings.

Super POLAR freezer foil

– used where temperatures drop below -30°C. Thanks to its modified composition, it remains flexible and durable even in extreme cold.

Super POLAR freezer foil

– used where temperatures drop below -30°C. Thanks to its modified composition, it remains flexible and durable even in extreme cold.

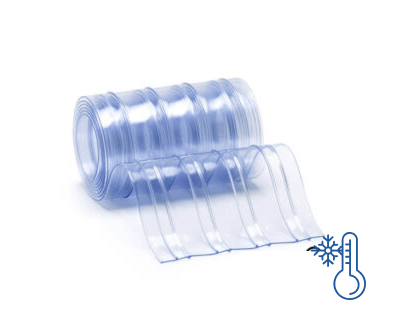

POLAR foil in a ribbed variant

– in 200 mm and 300 mm widths. Its surface has special protrusions (ribs) that minimize adhesion of the belts – especially when in contact with stretch film, commonly used for packaging goods in cold stores and warehouses. This prevents the curtains from sticking together, ensures free flow, and maintains their transparency longer. This is a practical solution for areas with high traffic and frequent contact with film packaging.

POLAR foil in a ribbed variant

– in 200 mm and 300 mm widths. Its surface has special protrusions (ribs) that minimize adhesion of the belts – especially when in contact with stretch film, commonly used for packaging goods in cold stores and warehouses. This prevents the curtains from sticking together, ensures free flow, and maintains their transparency longer. This is a practical solution for areas with high traffic and frequent contact with film packaging.

Both types of foil – smooth and ribbed – are resistant to moisture, frost and repeated flexing – which is crucial for their durability in refrigerated conditions.

2

Dimensions, thickness and belt overlap

Standard belt widths this:

200 mm – for pedestrian crossings and light wheelchair traffic, opening up to 3 m high

300 mm – for trolleys and medium traffic, opening up to 4 m high

400 mm – for large gates and intensive transport, opening height from 3.50 m to 6 m

Thickness of the strips also has meaning:

2 mm – most often used in cold stores with pedestrian traffic; ensures flexibility and low weight.

3 mm – recommended for passages with intense traffic and where the curtain is exposed to frequent mechanical contact (e.g. with trolleys, pallets).

4 mm and more – less commonly used in refrigeration, but useful in large doors or where greater resistance to drafts is needed.

Overlapping stripes affects tightness and insulation:

Single tab (approx. 36 mm) – basic insulation, optimal for most needs and solutions

Double pleat (approx. 54 mm) – a compromise between tightness and passage comfort. It increases thermal comfort but does not provide sufficient passage comfort.

3

Physicochemical properties of PVC foil

The PVC foil used in our cooling curtains is characterized by:

Hardness

Approximately 80 Sh A (according to EN ISO 868), which ensures adequate flexibility and strength.

Light transmittance:

Approximately 85% (according to ASTM D1003), which allows good visibility through the curtain.

Tensile strength:

The tensile strength is approximately 16 N/mm² (according to EN ISO 527), which proves the durability of the material.

4

Hygiene and safety

Cooling curtains made of PVC PRO are:

Safe for health:

They do not contain silicone or BPA, which is important in the food industry.

Easy to keep clean:

The smooth surface of the foil allows for easy cleaning and disinfection.

Resistant to chemical agents:

This allows them to be used in various industrial environments.

5

The most common mistakes when selecting and installing curtains

Incorrect selection of foil type:

Using standard foil instead of refrigerated foil at low temperatures leads to its stiffening and cracking.

Incorrect selection of foil type:

Too small an overlap may result in the curtain leaking.

Incorrect selection of foil type:

Improper fastening of the belts or the use of inappropriate fittings may lead to rapid wear of the curtain.