Industrial curtains

– when you want to keep order in the hall.

Industrial halls and production plants are spaces where everything must run smoothly. Work takes place in motion—machines, people, and internal transport. The problem is that physical boundaries between zones are often missing, leading to organizational chaos, noise, drafts, and unnecessary waste.

Industrial curtain is a solution that allows you to quickly and cheaply divide space, maintain order and control traffic in the hall.

Typical customer problems in industrial plants:

Noise, dust and dirt spread throughout the hall

The lack of zoning makes it difficult to organize production

Modernizing a hall means costs, formalities and downtime

Not everyone can afford to remodel or build walls. A solution that can be implemented immediately is needed.

PVC PRO Solution: Ready-made industrial curtain

You can use them to:

separation of production and transport zones, securing zones near machines or near noise sources, soundproofing work rooms.

Each industrial curtain PVC PRO is a ready-made kit that you can install yourself – without interrupting your work.

Configure your industrial curtain

Simply enter your dimensions and select the belt type in the configurator, and the system will prepare a ready-made set for you. If you have any questions, please call or email us. We'll be happy to advise you.

Loading configurator...

Technical information – INDUSTRIAL curtains

1

Dimensions and types of belts

100 mm × 2 mm

200 mm × 2 mm

200 mm × 3 mm

300 mm × 2 mm

300 mm × 3 mm

400 mm × 4 mm

2

Overlaps – tightness and insulation

For an industrial curtain to function effectively, strips alone are not enough – the way they are arranged is crucial, or overlap. This is simply the overlap of one strip over another, ensuring continuity of the cover and eliminating gaps between the strips during use.

The overlaps are selected depending on the width and thickness of the belts and the operating conditions:

For belts 100–200 mm we most often use the ok tab. 36–40 mm,

For belts 300mm – 54mm is a standard that ensures good tightness,

For belts 400 mm the tab is used even for 72 mm, which gives a very high level of insulation.

Larger overlap = greater tightness and better insulation, but also greater stiffness of the passage (which may be important, for example, for pedestrian traffic).

Bookmarks have great practical importance:

They stop drafts and heat loss,

Thanks to the use of pleats, the industrial curtain becomes flexible, semi-rigid partition, which, despite its simple design, effectively solves organizational and environmental problems in the hall.

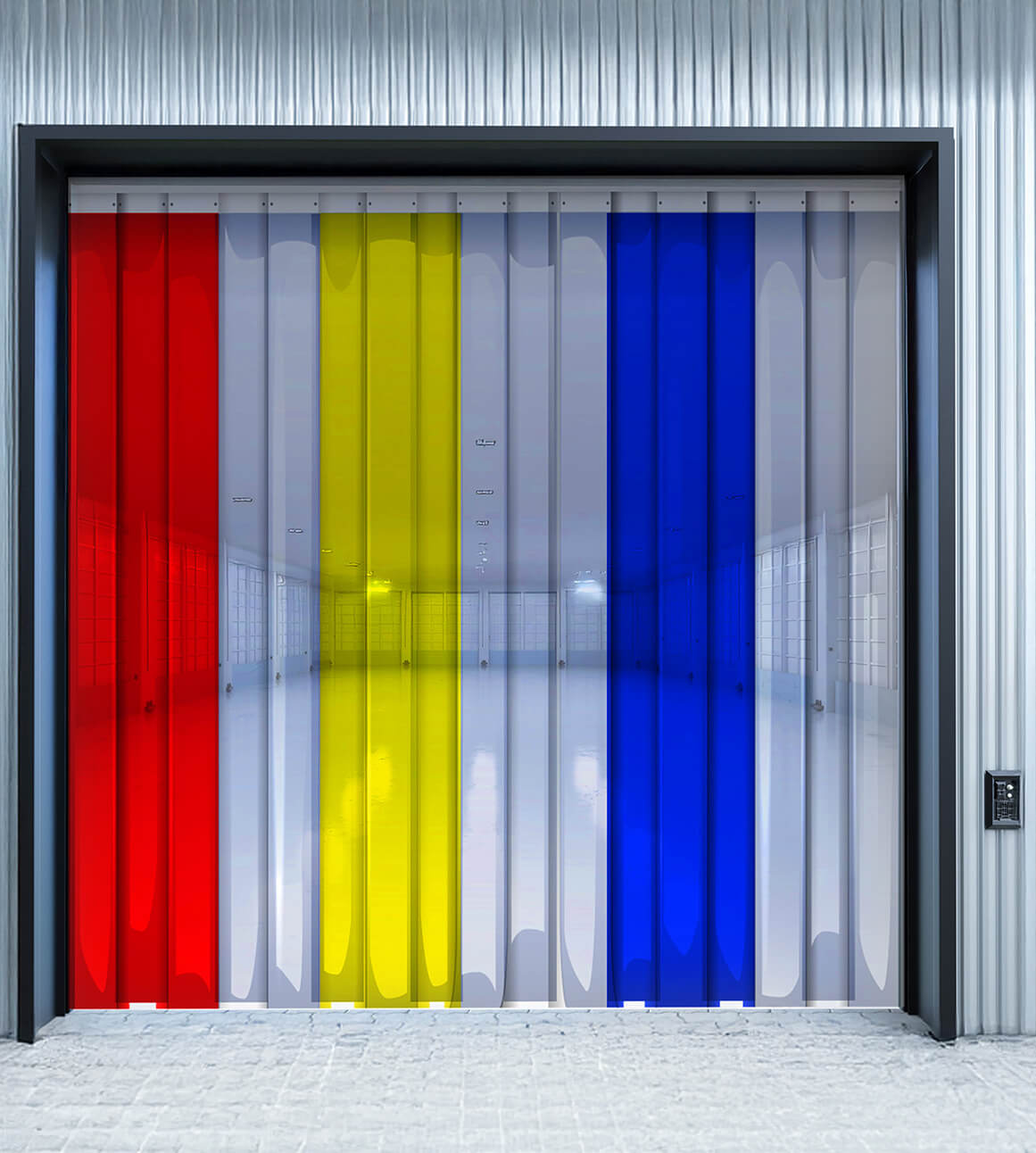

Colors and functionality

PVC PRO industrial curtains are available in several color variants and finishes, so they can be matched not only to the aesthetics of the hall, but – more importantly – to its functional requirements and organizational principles.

Color and degree of transparency

Transparent (colorless or slightly smoky) – this is the most frequently chosen option. They provide full visibility and visual control over what's happening on the other side of the curtain, without restricting daylight or spatial orientation. Recommended for circulation areas and places where safety requires good visibility.

Red and green (transparent) – In addition to their aesthetic function, they can serve as zone markings, warning signals, or spatial organization tools (e.g., red for danger zones, green for pedestrian traffic). They facilitate maintaining order and adhering to occupational health and safety procedures.

Matte – they limit visibility and light penetration. They are chosen where greater visual isolation is needed – for example, in areas requiring privacy or where structural elements should not be visible.

Ribbed belts – resistance and smooth movement

PVC PRO also offers ribbed belts, which are particularly well-suited for industrial halls with intense mechanical traffic – where regular belts could become worn, sticky or quickly degrade.

Ribbed belts have longitudinal projections along their entire length, which they perform two very important functions:

Increased mechanical resistance – The ribs act as a shock absorber, protecting the belt surface from abrasion caused by frequent contact with carts, pallets, machinery, and even people. Ideal for areas where the curtain is constantly in active use.

Reduced sticking For loads wrapped in stretch film, this is a common problem in logistics and production. Smooth straps can "stick" to the shiny surface of the stretch film, making transport difficult and causing jerking. Ribbing minimizes surface contact, allowing a forklift or operator to smoothly pass through the curtain without resistance.

Physical properties and protection

Impact and bending resistance – remain flexible all year round, even at lower temperatures,

Noise and draft reduction – a physical barrier limiting the spread of sounds and air between zones,

Insulation against dust and dirt – limit the spread of pollutants from one zone to another,

Flame retardant – the material is self-extinguishing (compliant with basic health and safety standards for industrial facilities),

Resistance to chemicals and lubricants – thanks to this, they are also suitable for industrial production and workshop areas.

Installation – permanent or mobile

Each set is delivered with pre-assembled straps, a comb strip, and a complete set of mounting hardware. Ready to hang.

Permanent installation – dedicated where the curtain is to divide the space permanently and there is no need to change the layout.

Mobile assembly – ideal for halls where space changes frequently or where a zone needs to be temporarily fenced off (e.g., service work zones, temporary storage, or temporary assembly). The frames can be equipped with casters.

Each set is delivered with pre-assembled straps, a comb strip, and a complete set of mounting hardware. Ready to hang.