Food Grade PVC Curtains.

Do you know this problem?

It is not easy to meet sanitary requirements and at the same time maintain workflow.

A regular curtain is not enough – hygiene is what counts here.

Standard PVC belts don't always meet the requirements of the food industry. A film that is resistant to disinfectants, steam, and temperature fluctuations, as well as having the appropriate certifications for food contact, is needed.

A ready-made solution – PVC curtains adapted to the food industry

PVC PRO food curtains are designed to meet the highest hygiene standards required in the food industry. They help separate production areas, protect raw materials and finished products, and are easy to clean.

Foil certified for food contact

Resistance to chemicals and temperatures

The foil is resistant to disinfectants, water vapor and changing temperature conditions, which ensures long-term use in the demanding conditions of the food industry.

Possibility of self-assembly without downtime

Configure your food curtain

Loading configurator...

What is worth knowing about strip curtains for the food industry?

1

Foil type – Food Contact

In the food sector we only use belts made of foil intended for contact with food (so-called "Food Contact").

Foil like this:

meets the requirements Regulation (EC) No 1935/2004 and Commission Regulation (EU) No 10/2011

has PZH certificate and other approvals enabling use in food production environments,

Is microbiologically safe, chemically neutral and does not emit harmful substances,

does not absorb odors or moisture, which prevents cross-contamination,

May be used in both dry and wet areas – e.g. in meat cutting, packaging rooms, fermentation chambers, cold stores.

2

Thickness and width of the stripes

In the food industry we most often use belts:

100 mm x 2 mm

200 mm × 2 mm

200 mm × 3 mm

– used in slightly wider openings and where there is more frequent movement of transport trolleys - a thicker belt ensures better stability and durability during more intensive use,

300 mm x 2 mm

300 mm x 3 mm

– in areas with intense traffic of trolleys, pallets, and washing equipment,

We select the width and thickness to ensure comfort of movement on the one hand, and to maintain tightness and durability in conditions of daily washing and intensive use on the other.

3

Overlaps – tightness in accordance with HACCP

The system of overlapping belts with an overlap is a way to ensure:

We select the width and thickness to ensure comfort of movement on the one hand, and to maintain tightness and durability in conditions of daily washing and intensive use on the other.

Single tab (approx. 36 mm)

– basic insulation, optimal for most needs and solutions

Double pleat (approx. 54 mm)

– a compromise between tightness and passage comfort. It increases thermal comfort but does not provide sufficient passage comfort.

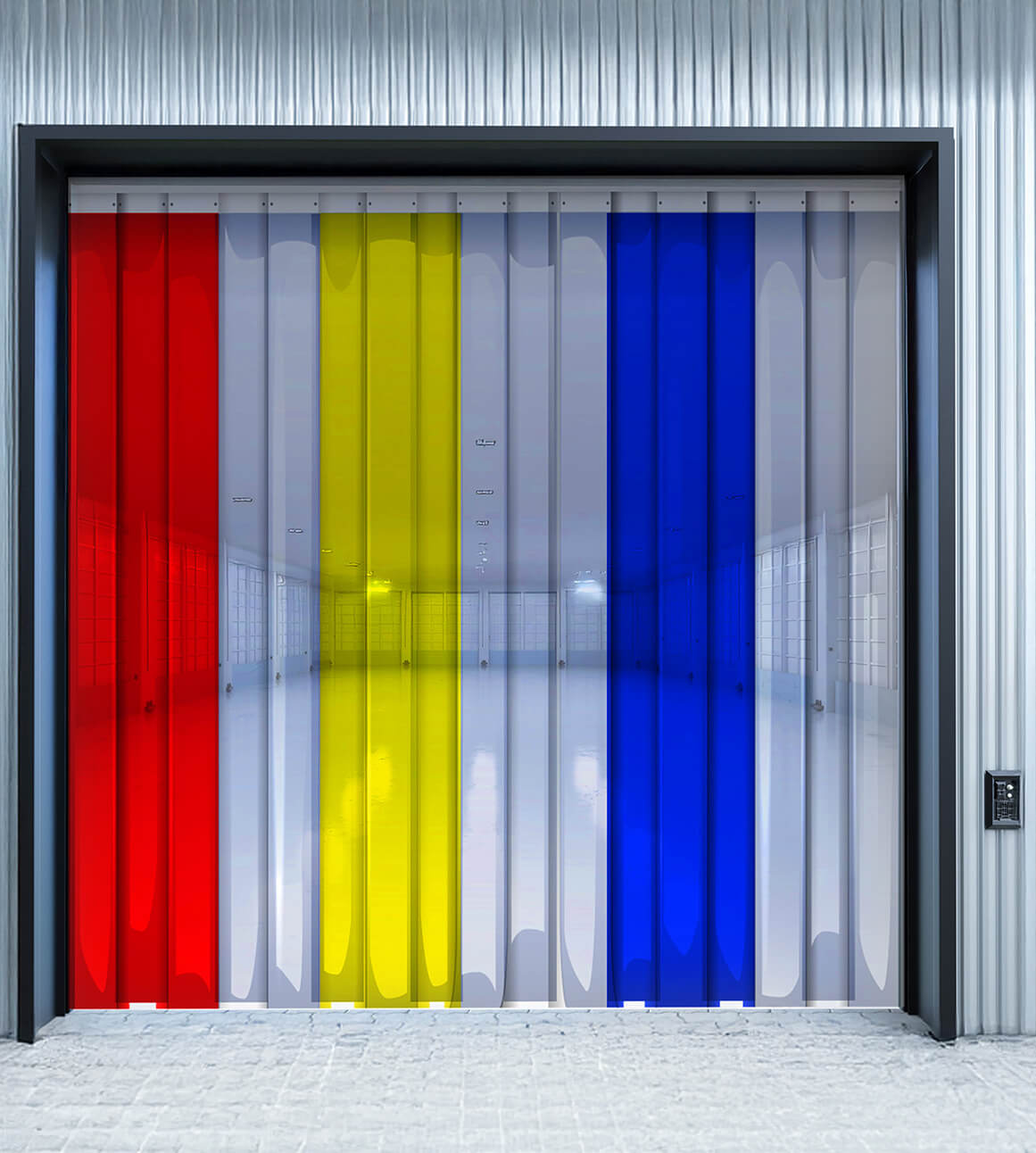

Color and transparency – organization and control

Although the most commonly used completely transparent stripes, versions are also available:

slightly matte – in zones where we want to partially limit visibility,

in shades of blue or milky – make it easier to distinguish work zones and improve work safety,

color stripes for markings – e.g. colored zones, transport paths, staff-only entrances.

The choice of color and transparency has organizational significance and can support work ergonomics and compliance with internal safety procedures.

Resistance to washing and chemicals

They can be dismantled and re-hung, which facilitates dry cleaning outside the production hall.

Regular cleaning does not affect the transparency or structure of the stripes – which is especially important for long-term use.

Installation – quick and hygienic

All curtains are made to exact dimensions – with precisely cut strips, selected pleats, and a comb strip. The finished set can be installed:

on the wall – from the front of the opening – most often used at the entrances to cold stores, production zones, cutting rooms, and packaging rooms,

inside the hole – under the lintel, e.g. at the entrances to production lines or in passageways.

Installation doesn't require specialized tools – all you need is a spirit level, a screwdriver, and a few minutes. All you need is a set. This solution doesn't disrupt operations, and if necessary, the curtains can be easily removed, for example, for cleaning.