Warehouse curtains – a simple solution to chaos, drafts and dangerous passages

A warehouse is a place where llogistical solutions must work without any glitches – and this means order, security and efficient flow of people and goods.

Unfortunately, in many halls and logistics centers the same problems occur: uncontrolled drafts, rising dust, illegible division of zones and the collision of the world of pedestrians with heavy transport.

A warehouse curtain is not an accessory – it is a simple and effective way to control this mess. No renovations. No downtime. No assembly crew.

Problems we know well from warehouses:

Drafts and heat loss

The openings between the zones are constantly open. In winter, it drafts, in summer, dust blows in. The air conditioning and heating go into the air.

No zoning

Noise, dust and confusion

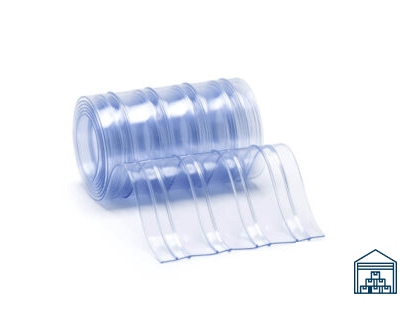

Our solution? PVC PRO warehouse curtain

Warehouse curtains help to quickly separate spaces from each other – bwithout building walls, without investing in expensive gates, without involving external companies.

They reduce drafts, heat loss and noise.

Transparent, durable, tailored to your needs – this is what a good warehouse curtain should be like. And this one from PVC PRO is just that.

Configure your warehouse curtain

Simply enter your dimensions and select the belt type in the configurator, and the system will prepare a ready-made set for you. If you have any questions, please call or email us. We'll be happy to advise you.

Loading configurator...

What is worth knowing about warehouse curtains?

1

Dimensions of PVC strips in warehouse curtains

Here are the most commonly used dimensions:

100 x 2 mm: Designed primarily for pedestrian crossings, they provide ease of passage and good thermal and acoustic insulation.

200 x 2 mm: Designed primarily for pedestrian and forklift access, they provide ease of passage and excellent thermal and acoustic insulation.

200 x 3 mm: An additional option used in wide, not high, openings.

300 x 3 mm: Universal strips used both in pedestrian crossings and in places with moderate forklift traffic.

300 x 2 mm: Additional low-cost option for 300 x 3mm

400 x 4 mm: Designed for intensive mechanical use, including forklifts and transport vehicles, they provide high resistance to mechanical damage.

Ribbed belts are available in only three dimensions:

200 x 2 mm

300 x 3 mm

400 x 4 mm

In the case of these belts, special ribs increase their resistance to mechanical damage and reduce adhesion to stretch packaging. The thickness of ribbed belts may be slightly greater (by 1–2 mm) depending on the manufacturer.

2

Overlapping stripes – importance for tightness and durability

Single tab (approx. 36 mm)

– basic insulation, optimal for most needs and solutions

Double pleat (approx. 54 mm)

– a compromise between tightness and passage comfort. It increases thermal comfort but does not provide sufficient passage comfort.

3

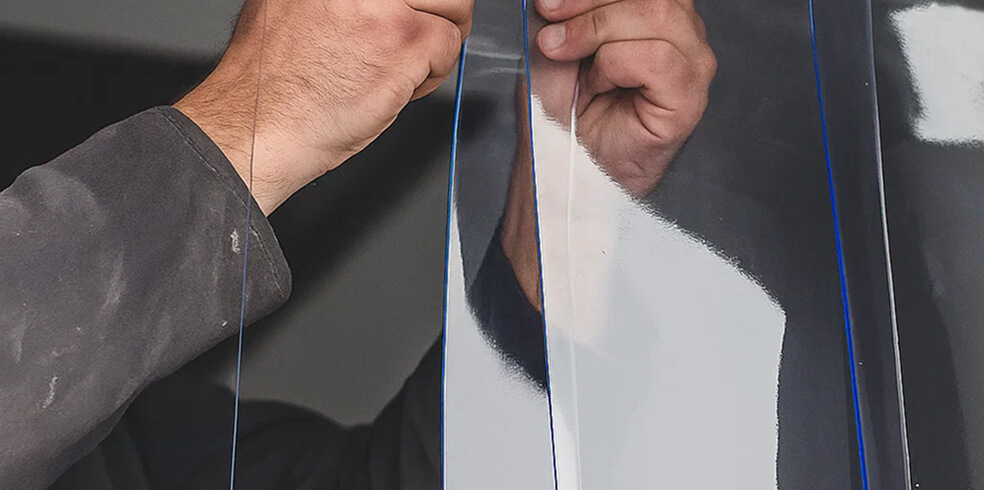

Ribbed vs. Smooth Belts – What to Choose in Stock?

Standard ribbed belts:

They do not stick to stretch film – this is their greatest advantage. Thanks to the longitudinal ribs, the contact surface between the strap and the load is significantly smaller. This means the curtain doesn't drag with the pallet, doesn't snag, and doesn't impede movement.

Increased resistance to mechanical damage – the ribs act as a shock absorber on impact, protecting the belt from abrasion or tearing.

Less friction between the belts – which means they do not stick to each other even in higher humidity.

Recommended in places with heavy traffic of machines and trolleys.

Standard ribbed belts:

They do not stick to stretch film – this is their greatest advantage. Thanks to the longitudinal ribs, the contact surface between the strap and the load is significantly smaller. This means the curtain doesn't drag with the pallet, doesn't snag, and doesn't impede movement.

Increased resistance to mechanical damage – the ribs act as a shock absorber on impact, protecting the belt from abrasion or tearing.

Less friction between the belts – which means they do not stick to each other even in higher humidity.

Recommended in places with heavy traffic of machines and trolleys.

Smooth belts:

More transparent – provide maximum visibility of the passage.

Easier to clean – the lack of recesses facilitates quick washing and disinfection.

Sufficient for standard pedestrian traffic or light transport.

Smooth belts:

More transparent – provide maximum visibility of the passage.

Easier to clean – the lack of recesses facilitates quick washing and disinfection.

Sufficient for standard pedestrian traffic or light transport.

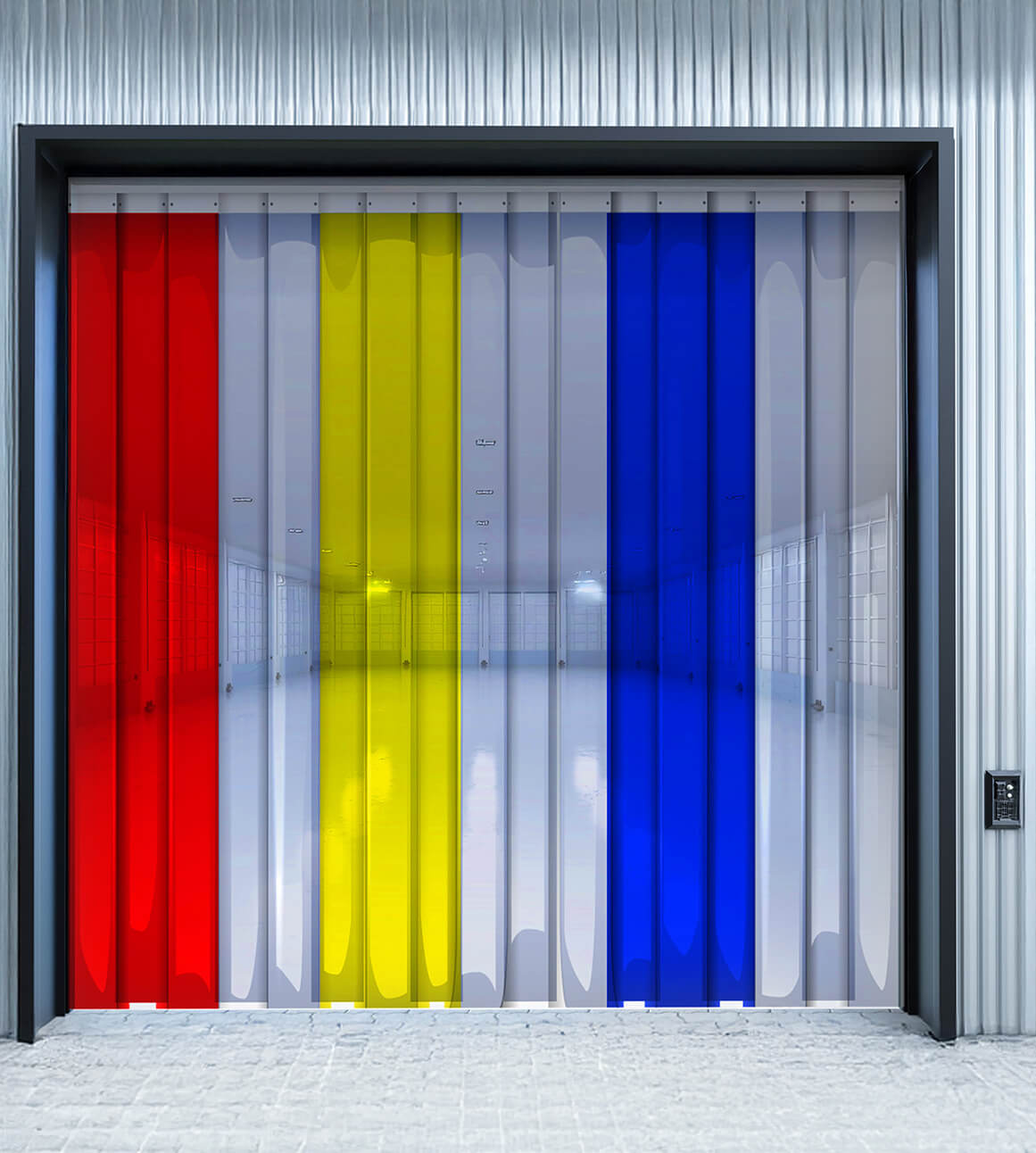

Belt colors – functionality and safety

Transparent: Standard, ensuring maximum visibility.

Red: Used as warning stripes on the edges of curtains, signaling the presence of a passage.

Blue, yellow, gray: Used to mark functional zones or for aesthetic purposes.

The use of colored stripes can increase safety by better marking passage areas and improve the organization of warehouse space.