Welding curtains – protection that meets standards and is safe

Welding zones are a demanding environment – It's not just about allocating space, but also about protecting health and ensuring safety. Unfortunately, many plants still secure their stands poorly – using tarps, screens, or curtains that do not meet standards and cannot withstand the conditions of the hall.

If you are looking for a solution that can be implemented quickly, works immediately and does not require major renovation, you are in the right place.

These problems are known to everyone who manages a welding hall:

Arc radiation blinds and endangers bystanders

All it takes is one unprotected flash to endanger the health of a nearby employee. The regulations are clear – you must protect your eyesight and skin.

Dust, filings and sparks escape from the work station

Improvised covers do not meet the standards and wear out quickly

Our answer: PVC PRO welding curtain

comply with the EN ISO 25980 standard (formerly EN 1598),

They allow people and strollers to move freely.

You can use them as:

partitions between stations, entrance curtains to welding cabins, movable welding curtains to separate temporary work zones.

Configure your welding curtain

Simply enter your dimensions and select the belt type in the configurator, and the system will prepare a ready-made set for you. If you have any questions, please call or email us. We'll be happy to advise you.

Loading configurator...

Technical information – welding curtains and drapes

1

Dimensions and types of belts

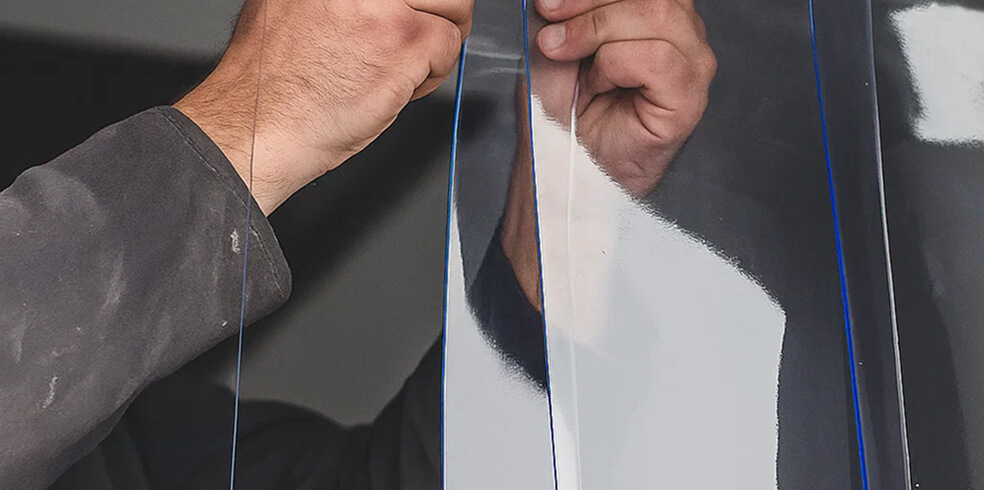

PVC PRO offers welding curtains made of certified PVC foil with increased resistance to radiation and mechanical damage. They are available in two versions:

300 mm × 3 mm

– a thicker option with higher resistance to tearing and contact with metal elements,

570 mm × 1 mm

– used in larger openings or as a screen with a wider range (e.g. in the form of curtains).

2

Overlapping stripes – importance for tightness and durability

Single tab (approx. 36 mm)

Double pleat (approx. 54 mm)

– a compromise between tightness and passage comfort. It increases thermal comfort but does not provide sufficient passage comfort.

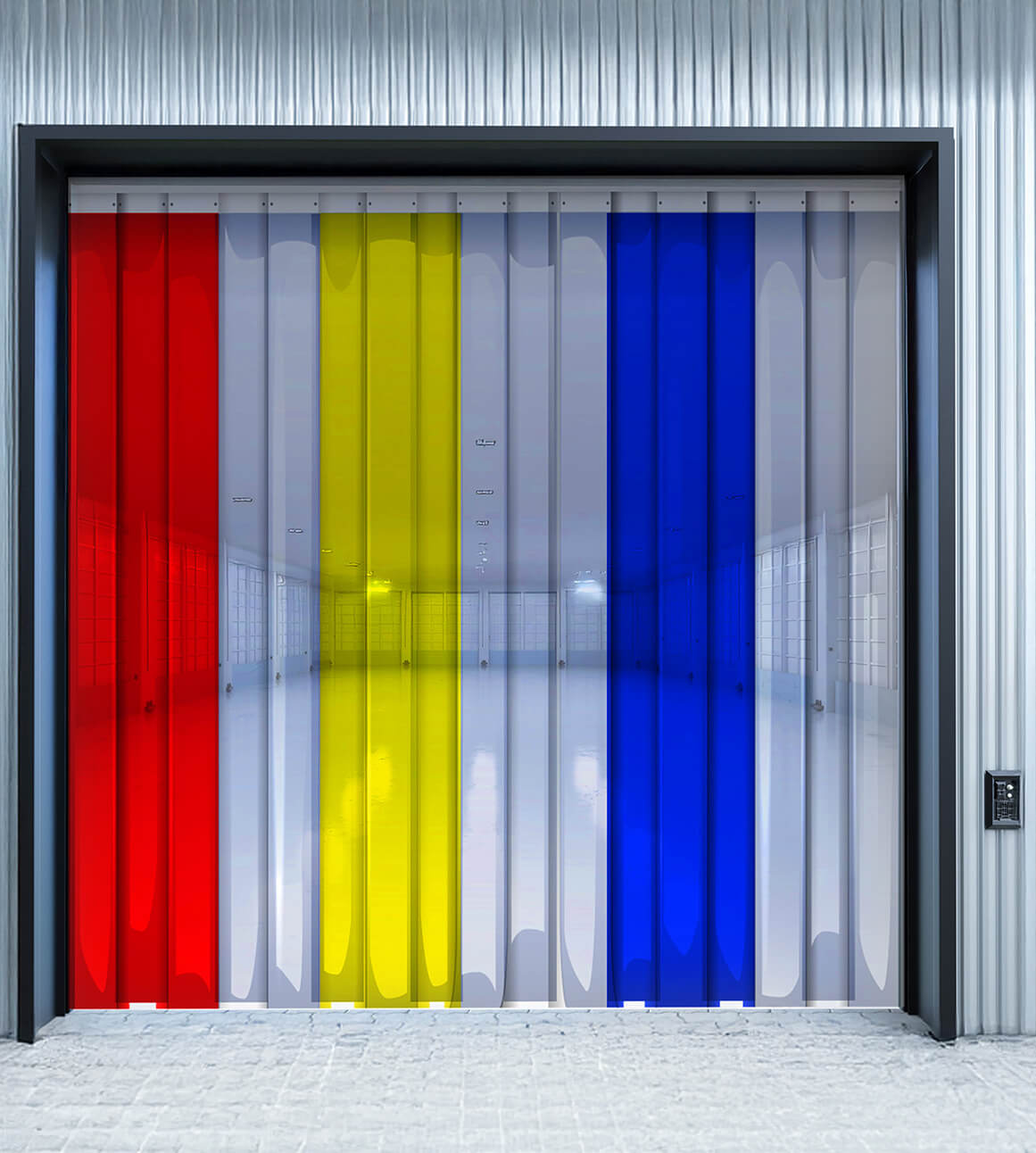

Available colors and transparency levels

Red – most often chosen due to good visibility and moderate transparency,

Green – an option with lower transparency, preferred where it is important to limit visibility from the outside.

Degree of transparency:

Transparent – allows you to control space while maintaining protection,

Mat – increases privacy and reduces light scattering.

Standards and protective properties – safety first

They protect the eyesight and skin of bystanders against UV and IR radiation generated during welding, cutting and grinding of metals,

They do not burn and do not drip with flaming drops – the material is flame retardant and self-extinguishing,

They reduce the risk of burns and eye injuries – Compliance with the standard means that the product can be used legally and safely in industrial plants,

They maintain optical stability – do not turn yellow or lose protective properties due to exposure to light and heat.

Additionally, compliance with the standard is not only a matter of safety – it is also meeting the requirements of the Occupational Health and Safety and National Labor Inspectorate (PIP) inspections. A curtain with a certificate = peace of mind and no consequences during inspections.

Assembly – flexible and adapted to the hall conditions

For permanent installation, the curtain is attached to a wall, ceiling, or steel structure using mounting hardware—a comb strip and forged metal plates. This method is effective wherever welding stations are permanently located and the hall layout is not subject to frequent changes. It ensures durability, stability, and complete protection without the need for daily rearrangement.

However, if your facility requires greater flexibility, portable welding curtain frames are an excellent solution. These frames allow you to move the curtain to a different location, place it at a new workstation, or temporarily section off a specific area. This is an ideal option for companies that work on a project-based or seasonal basis, or frequently change production layouts. Additionally, the frames can be equipped with casters, making transport and daily operation of the curtain easier – without any tools or interference with the hall's structure.

Thanks to this flexibility, PVC PRO welding curtains and drapes can be adapted to almost any workspace – both in a large industrial plant and in a smaller workshop or service point.